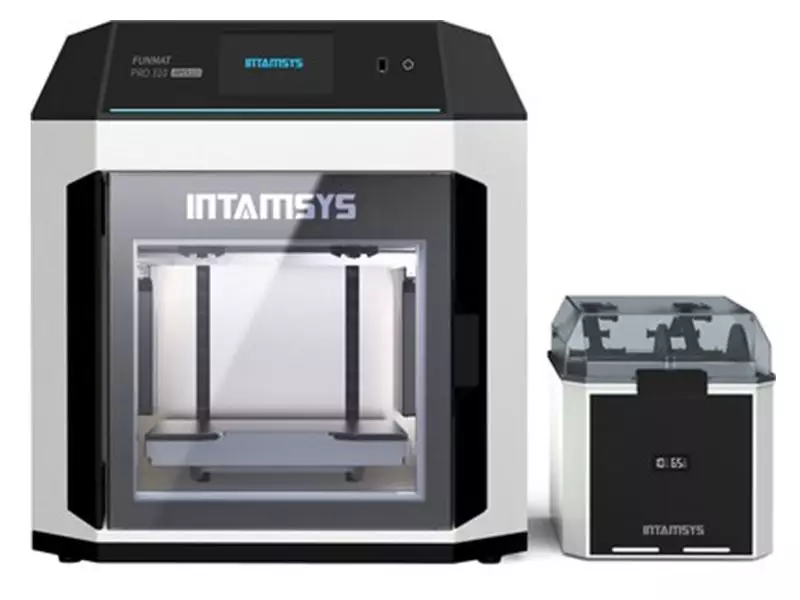

Intamsys, a global leader in industrial-grade 3D printing solutions, has officially launched the Funmat Pro 310 Apollo, marking a significant advancement in continuous production capabilities for high-performance materials. This cutting-edge system redefines industrial additive manufacturing by delivering unprecedented speed and strength in PAEK family material printing.

Revolutionizing Industrial 3D Printing Performance

The Funmat Pro 310 Apollo represents a major leap forward in high-temperature 3D printing technology, specifically engineered to meet the demanding requirements of continuous manufacturing environments. This industrial-grade system addresses the growing need for reliable production of end-use parts across aerospace, automotive, healthcare, and manufacturing sectors.

What sets the Apollo series apart is its exceptional capability to process advanced materials from the PAEK polymer family, including PEEK, PEKK, and ULTEM. These high-performance thermoplastics are renowned for their excellent mechanical properties, chemical resistance, and thermal stability, making them ideal for challenging industrial applications.

Advanced Technical Specifications and Features

The Funmat Pro 310 Apollo incorporates several groundbreaking technologies that ensure superior part quality and manufacturing efficiency. The system features an actively heated chamber capable of reaching 310°C, which is crucial for preventing warping and delamination during the printing of high-temperature materials. This advanced thermal management system ensures consistent results throughout extended production runs.

Building on the success of the original Funmat Pro 310, the Apollo variant introduces enhanced capabilities including improved printing speeds and superior part strength. The system maintains the proven dual extrusion system while incorporating optimizations that significantly boost productivity without compromising on the renowned dimensional accuracy and surface finish that Intamsys systems are known for.

One of the most significant advancements is the system's ability to maintain continuous production cycles, addressing a critical need in industrial manufacturing environments where downtime directly impacts operational costs and production timelines. This capability makes the Funmat Pro 310 Apollo particularly valuable for applications requiring batch production of functional components.

Transforming Manufacturing Across Industries

The introduction of the Funmat Pro 310 Apollo has far-reaching implications for multiple industrial sectors. In aerospace and automotive applications, the system enables production of lightweight, high-strength components that can withstand extreme environmental conditions. The medical industry benefits from its ability to create patient-specific implants and surgical guides using biocompatible materials.

Manufacturing enterprises can leverage the Apollo's capabilities for jigs, fixtures, and tooling that demonstrate superior wear resistance and durability compared to conventionally manufactured alternatives. The system's reliability and consistency make it suitable for producing end-use parts that meet stringent quality standards.

Industry experts recognize that the Funmat Pro 310 Apollo represents a significant milestone in making industrial-grade additive manufacturing more accessible and practical for production environments. By combining high-speed printing with exceptional material properties, Intamsys has created a solution that bridges the gap between prototyping and full-scale manufacturing.

The launch of this advanced 3D printing system comes at a time when manufacturers are increasingly adopting additive technologies to enhance supply chain resilience, reduce material waste, and create complex geometries that are impossible to achieve with traditional manufacturing methods. The Funmat Pro 310 Apollo positions Intamsys at the forefront of this industrial transformation.