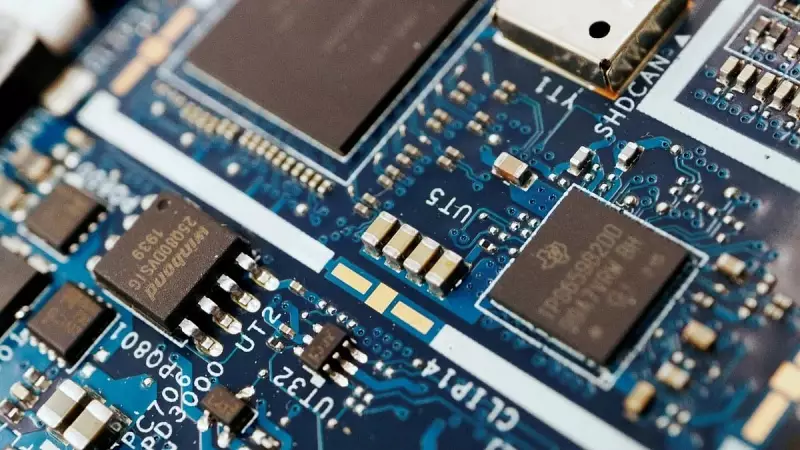

India faces a significant challenge in its electronics manufacturing sector, with experts revealing that the country imports a staggering 85% of its printed circuit board requirements. This critical dependency was highlighted during discussions at the Bengaluru Tech Summit, where industry leaders called for urgent scaling of semiconductor capabilities.

Alarming Import Dependency Figures

During the summit, Neeraj Pandita, Co-CEO of Wipro Electronics Materials, disclosed concerning statistics about India's PCB production capacity. Less than 5% of the company's PCB requirements are currently manufactured within India, highlighting the massive gap between domestic production and market needs.

The global context makes this dependency even more significant. The worldwide PCB market is valued at over $80 billion, while the laminates market - which forms the foundational material for creating PCBs - stands at approximately $20 billion. Both segments are projected to experience substantial growth in the coming years.

Opportunity for Domestic Manufacturing

Industry experts emphasized that this import dependency represents a massive opportunity for India to establish itself in the global electronics supply chain. With the right policies and investments, India could capture a significant portion of this growing market while reducing its reliance on imports.

The discussions at the Bengaluru Tech Summit focused on the need for comprehensive semiconductor ecosystem development, including PCB manufacturing capabilities. This aligns with India's broader ambitions to become a global electronics manufacturing hub.

Path Forward for Indian Electronics

The current scenario presents both a challenge and an opportunity for India's electronics sector. The heavy reliance on PCB imports not only affects the trade balance but also makes the industry vulnerable to global supply chain disruptions.

Experts stressed that developing domestic PCB manufacturing capabilities is crucial for India's strategic interests and economic growth. The call to action includes increased investment in semiconductor infrastructure, skill development, and policy support to create a self-reliant electronics manufacturing ecosystem.