A groundbreaking simulation study has finally pieced together the precise meteorological and environmental factors that turned the 2020 styrene gas leak in Visakhapatnam into a devastating tragedy. The research, conducted by scientists from the Indira Gandhi Centre for Atomic Research in Kalpakkam and the Homi Bhabha National Institute in Mumbai, provides a scientific post-mortem of the incident that claimed 12 lives and hospitalized hundreds.

The Perfect Storm of Conditions

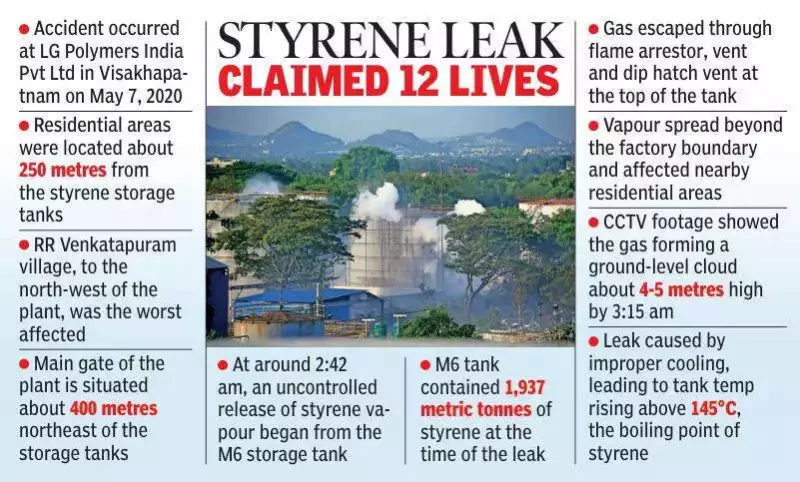

The catastrophic event unfolded in the early hours of May 7, 2020, at the LG Polymers plant in Venkatapuram, near Gopalapatnam. The study, employing a sophisticated buoyancy-modified WRF-FLEXPART dispersion model, reveals that a confluence of weather and release-related factors created a worst-case scenario. A crucial element was the timing: the leak occurred when the atmospheric layer was exceptionally stable, suppressing vertical mixing and trapping the gas close to the ground.

Compounding this was the extremely low wind speed prevalent at the time. This lack of wind meant the toxic cloud could not dilute or disperse quickly. Instead, it lingered stubbornly over adjacent residential zones for a prolonged period. Furthermore, styrene gas behaves as a heavy gas. Rather than rising and thinning out, it formed a dense, ground-hugging vapour layer, leading to intense exposure for people living in the immediate vicinity.

Massive Release and Directional Impact

The scale of the leak was a major amplifier of the disaster. Researchers note that approximately 800 tonnes of styrene gas was released over several hours, creating a vast and concentrated plume. The wind direction at the time was predominantly south-southwesterly, which acted as a direct conduit, channeling the poisonous cloud straight towards densely populated areas like Venkatapuram and its surrounding habitations. This unfortunate alignment greatly multiplied the impact on local residents.

The simulation's accuracy was validated against real-world data. The modelled wind direction, temperature, humidity, and atmospheric stability closely matched actual observations and radiosonde (weather balloon) data from the period. This alignment confirms the model's reliability in reconstructing the event.

Mapping the Danger Zones

Based on Acute Exposure Guideline Levels (AEGLs), the study clearly maps the perilous zones around the factory. It found that life-threatening concentrations (AEGL-3, above 1,500 ppm) extended to about 430 metres from the source. Meanwhile, concentrations serious enough to cause long-lasting or irreversible health effects (AEGL-2, between 100-1,000 ppm) spread much farther, reaching up to nearly 1.1 kilometres away.

The research team, comprising Shanu Karmakar, CV Srinivas, PT Rakesh, and L Srivani, highlighted a significant advancement in methodology. Unlike previous attempts to model disasters like the 1984 Bhopal gas tragedy, which were hampered by poor historical weather data, this study successfully integrated the actual meteorological and dispersion conditions from the 2020 incident. The modified FLEXPART model, which included buoyancy effects specific to styrene, produced results that matched the findings of the high-power committee investigating the leak, particularly regarding the critical north-northeasterly and northerly wind patterns.

This detailed simulation not only explains the past but also serves as a powerful tool for the future. It demonstrates how advanced modelling can help define vulnerability zones around industrial units, potentially guiding better emergency preparedness and urban planning to prevent such tragedies from repeating.